Combustion experiment of NN OIL

Test site

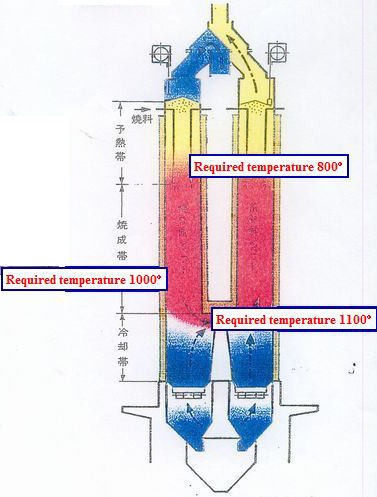

The test kiln conditions

|

|

|---|---|

| Lime production plant see the on-site pictures | MAERZ KILN To the manufacturer site for more information To see the MAERZ KILN |

- Combustion chamber volume : 140 m3

- Air ratio : 0.7

- Addition of water rate : 30 %

On site progress pictures

Test site - Lime production plant

Date: 9 Feb 2013

Progress report

The examination conditions are as follows.

Notice:Amount of carbon dioxide is not the absolute figures. It's the calculated value as below.

Calculating formula

- Testing period : 1 Nov to 6 Dec 2012

- Testing method :The CO, O2 measurement with the measuring instrument : "HT-1600" made in HODAKA CO., LTD.

- Testing place :Smoke vent of test furnace and Comparison furnace in the Lime production plant

| Classification | CO(ppm) | CO(%) | O2(%) | NOX (ppm) | The air ratio | gas temperature |

|---|---|---|---|---|---|---|

| Test furnace | 65.5 | 5.8 | 13.3 | 78.5 | 2.8 | 59.8 |

| Comparison furnace | 117.0 | 7.0 | 11.8 | 79.1 | 2.3 | 63.2 |

| Difference | -51.5 | -1.2 | +1.5 | -0.6 | +0.5 | -3.4 |

| Type of fuel | GO(Nm3) | AO(Nm3) | Calp(kcal/Nm3 or kg) | CO2Max |

|---|---|---|---|---|

| Diesel Oil | 11.9 | 11.15 | 10280kcal/kg | 15.4 |

| Bunker A | 11.37 | 10.68 | 10160kcal/kg | 15.8 |

| Bunker C | 10.88 | 10.25 | 9750kcal/kg | 16.0 |

Opinion

Opinion due to the measurement data as follows.

The above-mentioned situation is considered to be the overoxidation and the cooling effect by excess intake air.